Description

Technical Parameters

Brief Introduction

Engineered to eliminate mechanical shock during startup, this soft starter liquid rotor starter progressively regulates voltage through phase-controlled thyristor ramping, delivering smooth torque buildup without frequency conversion.

Core Starting Technologies:

Controlled Current Ramp: Limits inrush currents to 6-7 times below direct-start overload levels, preventing shaft torsion failures and mechanical stress.

Thyristor Voltage Modulation: Gradual conduction angle adjustment enables stepless voltage elevation from zero to rated supply, eliminating torque spikes.

Cost-Efficient Simplicity: Pure voltage regulation (non-frequency conversion) ensures lower complexity and maintenance costs versus VFD alternatives.

High/Low Voltage Adaptability: Standardized thyristor stacks support both MV/LV applications with unified control logic.

Critical implementations include:

• Pre-programmed torque curves for centrifugal pumps, conveyors, and compressors

• Bypass contactors engaging after run-up completion to minimize heat dissipation

• Insulated gate drivers with snubber circuits suppressing voltage transients

• Thermal-derating protection during extended starts

The CMC-LX 160-3 unit executes:

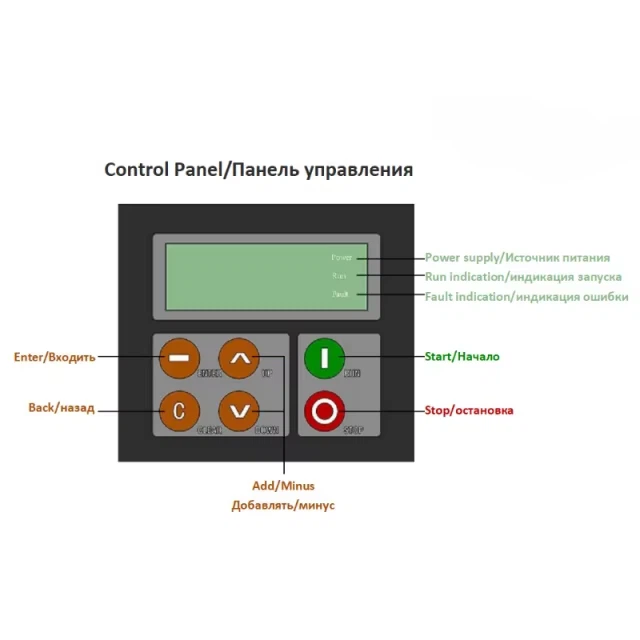

Adjustable current limiting via rotary dial interface

Real-time monitoring terminals for voltage/current validation

DIN-rail compatible control modules reducing cabinet footprint

NEMA 12 enclosure guarding against dust ingress

Validated for 380-690V systems, it extends motor lifespan through shock-free acceleration while eliminating gearbox/bearing damage common in uncontrolled starts. Excludes frequency manipulation capabilities for dedicated voltage-regulation applications.

Mounting

Production Details

Frame

-

Compact and robust iron casting frame

-

Universal IEC and NEMA installation dimensions

-

Customizable

Stator

-

99.9% pure copper winding for stator to ensure the output power and efficiency

-

Excellent insulation system with 5 more processing flows

-

All the windings are fitted in by handwork to ensure all slots are full and avoid any winding flaw.

Rotor

-

Aluminum casting rotor with silicon steel rotor core to assure induction efficiency

-

Precisely machined shafts with good capacity of strength and toughness

Testing

-

All motors must pass the piece testing before painting and packaging

-

Type tests will be regularly performed for each series, more often for new developed series and variants.

Package and delivery

-

All motors will be packaged well before delivery

-

Plastic cover inside, vacuum tin foil outer and then solid wood box

Applications

This series of motor is commonly used to drive water pumps, compressors, conveyors and other transmission machinery in different areas.

Chemistry

Power Station

Cement

Pump

|

CHOOSE SIMO, CHOOSE QUALITY! |

Hot Tags: liquid rotor starter, China, suppliers, manufacturers, factory, customized , quotation, low price, in stock, made in China

Previous

No InformationSend Inquiry